Little Known Facts About American Plastics.

Table of ContentsThe Ultimate Guide To American PlasticsThe Ultimate Guide To American PlasticsThe Greatest Guide To American PlasticsNot known Facts About American PlasticsAmerican Plastics Fundamentals Explained

A little research can aid you gradually. It is tough to judge its high quality at first glance with the appearance of HDPE pipeline fitting, lots of defects are subjected when making use of, so we can only have a correct judgment after use. It is required to pick HDPE pipeline installations made by a specialist supplier with a great track record and credibility.

A technical expert is necessary for a good product, particularly in the manufacturing market, since a little error will cause the failing of the entire job. HDPE pipes can replace concrete pipes in area systems to conserve time and price of fixing busted or burst pipelines. HDPE pipeline is additionally a much less pricey choice contrasted to various other piping products in terms of operating and installation costs.

Some Known Details About American Plastics

HDPE pipes are produced with solid straight or curved sections. The pipelines are not brittle and can be conveniently placed right into a curved area without extra jointing or welding.

Chemicals resistant to HDPE pipes can pollute the pipeline. The pipeline does not work with chemicals and does not burn warm or electrical energy.

HDPE pipelines are naturally solid and resistant to damages brought on by exterior tons, high stress or vibration - https://americanplastics.bandcamp.com/album/american-plastics. The pipelines can endure handling and bend even in winter. Safe eyeliner HDPE internal tubing Smooth Line Pipe Moving lining using roller mixes Pipeline explosion Plastic pipes systems Construction of new pipelines Corrosion resistance, no leaking, high resilience

Heat combination, while its obstacles exist, can develop solid and reputable joints. Responses: The toughness and longevity of HDPE can be gauged by its capacity to stand up to temperature levels of around 248F in the short term or perhaps a constant 230F. If your application consists of gas and liquid to accessibility and raise those temperature levels, HPDE piping is a trusted service.

Indicators on American Plastics You Need To Know

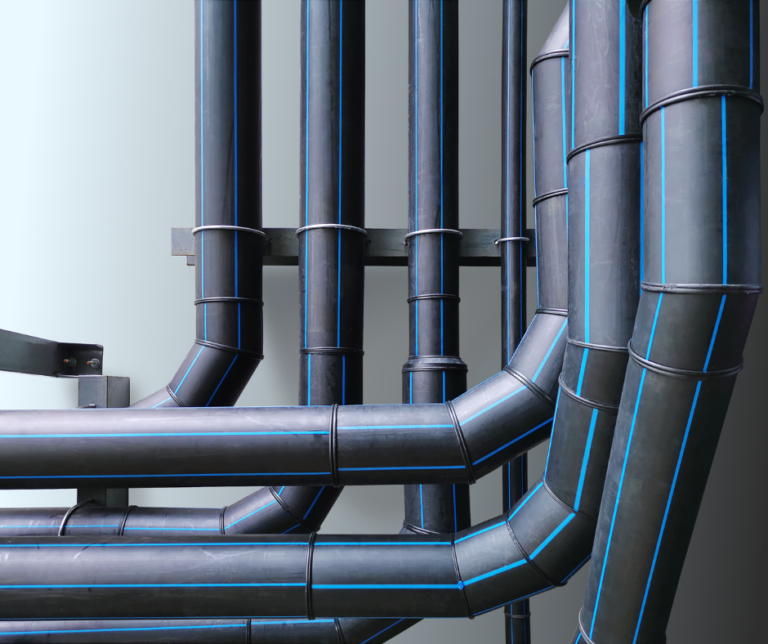

A safe and clean water line/potable water pipe is always dark with blue stripes and pipes passing through liquids, fluids under stress, and process gases are constantly filled up with a yellow or black coat with yellow lines. HDPE pipeline material have been utilized in the basic sector for over half a century and their results are astonishing, constructing self-confidence amongst producers that they are more focused on HDPE pipeline solutions.

Times considering that 1991 Removal of resin demands with scale and change. In the tension crack resistance test the cellular division demands were deteriorated. It is affordable to wrap up that HDPE pipe constructed today may have.

Each size classification is developed maintaining in mind the demands of pressure, circulation rate, and ecological aspects of the designated application. By matching the right HDPE pipeline size to its use, engineers and specialists can optimize efficiency and extend the life expectancy of their piping systems. Measurement and diameter are related ideas in the context of HDPE pipes.

Getting My American Plastics To Work

As mentioned previously, pipelines with reduced SDR values are able to endure higher stress, which is an important factor to consider in the choice procedure for projects that include high pressure or vital applications. high quality hdpe pipe. Selecting a pipe with an inappropriate SDR can bring about system failing, security threats, and expensive repair services. Selecting the proper HDPE pipe dimension is critical for the success and effectiveness of any kind of piping system

Application Specifics: Customize your pipe dimension selection to the specific needs of its application, whether for metropolitan, commercial, or various other usages. Understanding just how the HDPE pipe will be used, the anticipated flow rates and the pressure requirements are important. High-pressure applications might require a pipeline with a better Visit This Link wall thickness to hold up against the interior stresses, while a lower-pressure, high-flow system might prioritize diameter size to decrease rubbing loss.

Facts About American Plastics Uncovered

Comply with these steps: Analyze the Application: Establish the pipe's intended use, consisting of environmental aspects and solution problems. Refer to SDR: Inspect the conventional measurement ratio to find a pipeline that can take care of the required pressure.

Picking the appropriate HDPE pipeline dimension is a delicate balance in between various technical specs and functional demands - https://www.openstreetmap.org/user/americanplastics. With careful consideration and accurate calculations, you can make sure the dimension of the pipe you choose will certainly serve your demands effectively and efficiently. Picking the correct HDPE pipeline size is critical for system performance, resilience, and cost-effectiveness

Comprehending these facets will certainly make sure optimum efficiency and compatibility throughout your piping system - hdpe pipe fittings Midland TX. The expected circulation rate or volume of the liquid being transferred is one of the key factors in pipeline size choice. A pipeline that is as well little can limit flow, triggering stress loss and prospective obstructions, while an extremely big pipeline might result in unneeded expenditure and reduced system performance